“Decarbonized Minoyaki SDGs Project” started! |Press release from Toki Municipal Ceramics Experiment Station, Ceratechno Toki

Mino-yaki eco-yaki poster

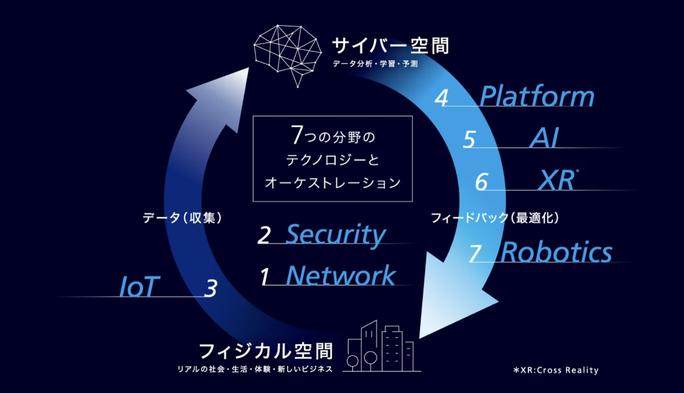

In the "main firing process" of the ceramics manufacturing process, high temperature heating of 1300°C with LP gas is required. It is the current situation that a large amount is discharged. It must be said that the possibility of achieving virtually zero emissions of carbon dioxide (decarbonization) is extremely low with current technology, but there are reasons why giving up on decarbonization and doing nothing is justified. I thought that it would not be possible, and decided to start an initiative to reduce carbon dioxide emissions as much as possible in order to fulfill that social responsibility. Pottery is heated in a kiln at a temperature of about 1250°C, and porcelain at a temperature of over 1300°C. This process is called "firing", and the mainstream of Mino ware is to use a gas kiln that uses LP gas as fuel. There are two types of firing: oxidizing firing, which takes in enough oxygen, and reduction firing, which restricts oxygen. The coloring of iron and copper contained in the glaze differs between oxidation and reduction, and the firing atmosphere varies depending on the product. Reduction firing has the effect of making the porcelain whiter, so it is used in many Mino wares. Ceramic manufacturers usually have a strong commitment to this "firing". In response to the seemingly contradictory themes of commitment to firing and reducing fuel consumption, we are taking on the challenge of achieving both commitment to firing and low carbonization by further refining the technology we have cultivated over our long history. I'm thinking of going. The first challenge is to "reduce the fuel consumption rate by reviewing the firing conditions." We will distribute 6 types of achievement display stickers to ceramic manufacturers according to the degree of reduction in fuel consumption rate. -5% reduction, -10% reduction, -15% reduction, -20% reduction, -25% reduction, -30% reductionsticker

Distribute stickers according to the reduction rate

Please check the official website for a list of companies participating in the decarbonized Minoyaki SDGs project. https://www.city.toki.lg.jp/docs/17248.htmlToki City, Gifu Prefecture About the 1400-year history of Minoyaki The city has developed as a pottery production area with a history of 1,400 years because of its abundance of high-quality pottery clay (clay) suitable for ceramics and Japanese red pine, which is used as fuel (firewood) for firing. Beginning with the production of Sue ware in the 7th century, during the Azuchi-Momoyama period in the 16th century, tea pottery and high-class tableware such as Oribe, Shino, Kiseto, and Seto-guro were created, and these works are highly evaluated worldwide. I am receiving From the 17th century onwards, the production of tableware for daily use became the main focus, and mass production progressed after the Meiji period, forming the foundation of the ceramics industry, which is the key industry of Toki City. In Toki City, there are kilns built between the 7th century and the 17th century, including the ``Motoyashiki Pottery Kiln Site'', which is designated as a national historic site. You can also see a brick chimney for In this way, Mino ware has developed with both cultural and industrial value, and today there are more than 260 potteries (manufacturers) that manufacture products ranging from household use to business use, high-end products to mass-produced products. We manufacture Mino ware while responding to all needs. At present, it accounts for about 40% of domestic production of tableware and kitchen tableware, and is said to account for about 60% if other ceramics such as tiles are included. In other words, it is no exaggeration to say that Minoyaki is on the dining table of every household across the country. Access to Toki City, Gifu Prefecture By car: From Toki IC on the Chuo Expressway. From Toki Minami Tajimi IC or Gotomaki Smart IC on the Tokai-Kanjo Expressway. Train: Get off at Tokishi Station on the JR Chuo Main Line.

![lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool] lifehacker lifehacker LifeHacker LifeHacker A carabiner that is convenient for cutting packaging at the entrance. Excellent sharpness for medical blades! [Today's life hack tool]](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/28016.jpeg)

![lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/223/2022-3-2/30293.jpeg)

Kitchen Equipment Every Restaurant Needs

The IKEA wood box was a great help in preparing breakfast! There are too many other uses ~

lifehacker lifehacker LifeHacker LifeHacker [2021] 7 Recommended Dishwashers | Introducing High Cospa & Compact Products

Just put it on the cafe feeling at once!Enriched Cafe Item in Nitori (January 24, 2022) --Excite News